by Davoud Sultani

Conductive thread is a thread that conducts electricity. Conductive threads are a cross between the world of electric wires and the world of textiles, with attributes of each. Historically conductive thread in a more general definition have played a role in innovation, dating back to the use of a carbonized sewing thread used as a filament in Thomas Edison's light bulb. Of the hundreds he tried, this was the first filament that met his needs for resistance and lifespan.

Nowadays conductive thread consist of two major groups:

A. Intrinsically conductive threads made out of conductive fibers which are conductive by the very physical and chemical nature of the basic fiber. Included in this group are metallic wire, graphite fibers, intrinsically conductive polymer fibers and carbon nanotubes. The most commercially available member of this group are

those made from stainless steel fibers which offers a very low electrical resistance (in the range of a few Ωs per meter). In general this sort of conductive thread is too delicate to run through a needle of a consumer sewing machines and it should be wind onto a bobbin or couch onto the project.

B. Nonconductive

or less conductive core, which are then either coated or embedded with an electrically conductive element, often carbon, nickel, copper, gold, silver, or titanium. These core threads typically include cotton, polyester, nylon. This sort can generally be used in a normal sewing machine. Their resistance varies greatly based upon the metal used in the coating (silver being the most common choice) and the thickness of the coating layer.

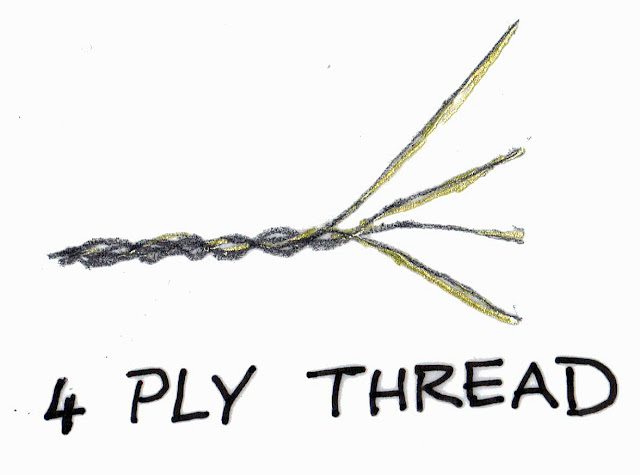

Conductive thread is normally not insulated and comes in different coatings and/or number of plies. It can be used similarly to wire to allow a path for current to flow although it is not an efficient alternative for wiring or traces on a printed circuit boards but it is efficient enough to cover a wide range of applications.

Usage

Conductive thread is used in many industries, including military, aerospace, aviation,medical, textile, transportation. Uses for conductive thread and textiles may include static dissipation, electromagnetic shielding, intelligent textiles, wearable technology, signal, power and data transfer in low resistance versions, and as a heating element in higher resistance versions. Their benefits over solid or stranded metal wires come from conductive thread's flexibility, low weight with high strength, extreme durability in some cases, and the ability to use them in existing textile and wire machinery (weaving, sewing, braiding, twisting, stranding, etc.) Some conductive threads have high temperature durability and can be soldered like solid wire. Some of the applications of conductive thread in day to day life are in fencing lamés (jacket for detecting hits), heating purposes in special heating wetsuits, smartphone and tablet friendly gloves and clothing with embedded electronics (i.e. T-shirts with glowing logos and biker jackets with LED signs in their back).

One of the most common uses of conductive thread in the scientific and industrial scenes

is for making anti static garment, carpets and other items that dissipate static electricity

(i.e. protective clothing for use in the manufacturing of electrostatic sensitive devices).

Another more recent use is in the production of 'Stun gun' or Taser proof clothing, where

the conductive thread is used as a sort of Faraday shield in a layer of the garment in

question. This application of conductive thread can come quite handy for the anarchist

activists amongst us.

There’s a washable arduino called Lilypad Arduino specifically developed for the purpose

of using with conductive thread for DIY projects.

Durability

The durability of conductive threads varies greatly amongst the many different kinds of it

that are available for public to purchase. In general type A conductive threads are harder to

use but more durable.

Depending on its material and its application there are different instructions on how to

wash a fabric with conductive threads used in it. In general to protect the coating layer it is

advised to hand wash with a mild detergent in a water not warmer than 40 degrees celsius.

For instance in case of silver coated threads, there’s consensus that the coating tends to

start wearing off after a few times of washing, resulting in higher overall resistance in the

circuit. It is advised to place the main elements as close as possible reducing the effect of the higher resistance. One can also coat the thread with silver polish upon noticing

remarkable resistance hikes.

this blog is dedicated to the Bucky Lab from the TU Delft faculty of Architecture. Within the mastercourse we design, develop and at the end build architecture and building construction related prototypes. Its a "get your hands dirty" approach in which the students learn how to translate concepts from sketch into working prototypes. We try to live the spirit of buckminster fuller: what ever you can imagine, you can also build!