Oh oh oh ...after some problems yesterday we went to bed with mixed feelings...but with a solution in

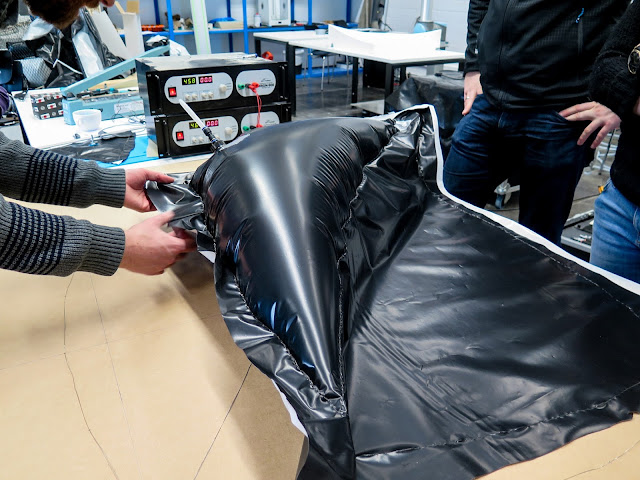

mind: splitting up the heating wires and connect them in parallel to the power source in the case we are not able to get power sources up to 60 V ...

And the wonder this morning came in the person of Pit head of the faculties workshop who joined shortly early in the morning ...Ah Marcel I have a set of power sources down there that should do the job perfectly...and after a quick check it worked perfectly. So the first batch of elements were suscessfully welded.

Next improvement due to the fact that we have to weld at least 4 different outer panels and the time consuming process of fixation with an ultra thin wire we tested a heat resistance tape to fix the heating wire. If that works we are able to change the geometry quickly.

First tests of this method already showed that it requires a bit more power but resulted in a more

precise welding line ... We keep you posted while we are crossing fingers for tomorrow.

While most were busy with the welding technique one group were busy to develop a design for the light design and good old black light seemed to be the best option. and honestly we all liked the lightshow the team had prepared in our units toilet ...and Alex was able to did the icing on the cake with our strobe light ...

the robot was unemployed today and made a sad face ...

this blog is dedicated to the Bucky Lab from the TU Delft faculty of Architecture. Within the mastercourse we design, develop and at the end build architecture and building construction related prototypes. Its a "get your hands dirty" approach in which the students learn how to translate concepts from sketch into working prototypes. We try to live the spirit of buckminster fuller: what ever you can imagine, you can also build!